- Mitsubishi’s state-of-the-art D-Cubes controller

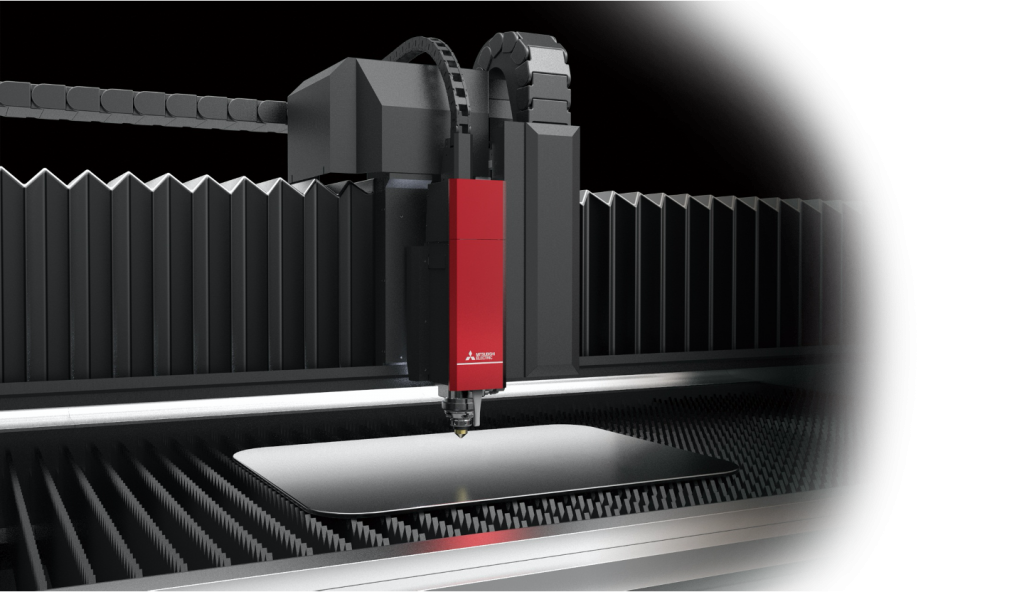

- Mitsubishi AGR eco (advanced gas-reduction Zoom Autofocus cutting head)

- The industry’s best magnetic breakaway fiber head

- One-button press automatic safety door and side access

- Two high-pressure-assist gas ports

- Work lifter

- All-in-one head design

- HPP Pierce technology

- Barcode reader

- Autofocus focal range from 3.75 – 10 inches

- Flexible beam mode to cut thin and thick material automatically

- No lens cleaning required

- No cartridge changes

- Reduced nozzle centring

meet the Mitsubishi GX-F FIBER LASER

This machine sets the standard for what fiber lasers are capable of, pushing aesthetics, design and artificial intelligence as far as it can go.

The GX-F series is constructed using trailblazing fiber laser technology that ensures unprecedented cutting speeds at a wavelength of 1.07um.

Mitsubishi Electric is a world leader in industrial electronic controls and components and part of their mission is to provide the best products and services with unsurpassed quality.

The future is now!

MITSUBISHI’S LATEST D-CUBES CONTROLLER

Intuitive operation with multi-touch panel

Easily swipe to the required screen. Graphics can be easily scaled.

Customisable icons

Users can freely customise the icons on the screen, keeping only the necessary information.

Easily move the processing head with screen operations

Simply touch the destination on the screen and press the movement start switch to move the processing head to the specified position.

Mitsubishi Fiber Laser

Zoom Processing HEAD

Mitsubishi’s “Zoom” processing head, manufactured in-house, utilises Mitsubishi Electric’s proprietary optical technology and provides optimal control of the beam according to the material and plate thickness.

This provides reliable processing for all thicknesses and supports stable production at the processing site. Also, the range of selectable processing conditions has been expanded, making it unnecessary to exchange the processing lens according to the plate thickness and material, shortening the setup time.

Mitsubishi Fiber Laser Oscillator

Mitsubishi’s in-house fiber laser oscillator achieves both high reliability and high productivity and is backed by a 5-year manufacturers warranty.

Advanced control of many separate laser modules greatly improves the longevity of the system and minimises any risk of failure.

AI Assistance

Maisart® AI-processing technology ensures stable processing, improved edge quality, and reduced burr that is both reliable and consistent.

The cutting head is equipped with a state-of-the-art light sensor and microphone. These two components actively listen to and watch the cutting process in real time. The AI will then assign each cut a rating in terms of quality. If the rating is poor, the cutting parameters will be accordingly adjusted to ensure stronger, more efficient processing.

Mitsubishi Fiber Laser

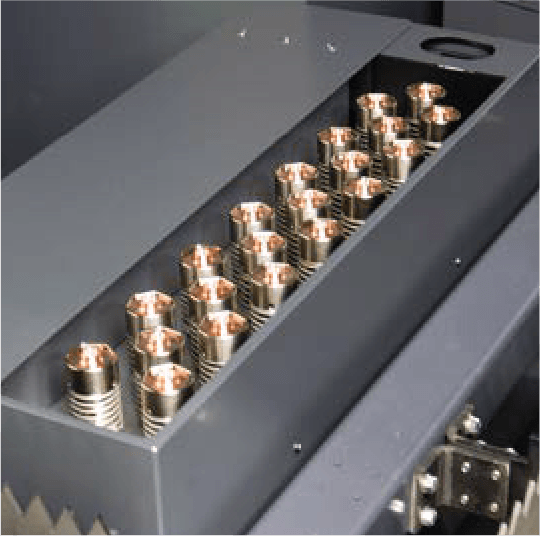

NOZZLE CHANGER

The nozzle changer can be equipped with up to 21 nozzles. Nozzles determined defective by the nozzle monitor are automatically replaced with new ones to support continuous processing for a long period of time. The ideal nozzle for processing can be selected from various types of nozzles, with more options than have conventionally been available.

TECHNICAL INFORMATION

- Mitsubishi Electric’s all-new D-Cubes series control features a 19-inch touchscreen and many updated features to increase cutting speeds and productivity

- The standard 19″ touch screen provides smartphone-like intuitive operation with a keyboard and mouse for added control

- Processing speed up to 100m per min (up from 50)

- Customisable home page and status bar using shortcut icons. This means fewer button presses to perform the same process.

- On-button safety-door operation

- Expanded cutting-condition library with more condition lines and piercing options. There are now 20 condition lines.

- Easy condition and program search

- Updated production schedule for standalone machines

- Edit up to two programs at once

- Expanded maintenance and help screens

- Improved process time on small-geometry intensive parts due to better acceleration and deceleration

- The advanced dross-reduction control increases cutting speed in tight geometries and holes

- New 5-colour light tower depicts operational status and part time remaining

- Windows 8e operating system

- The number of usable programs is now 1000 (was 400)

- The machine now has two 3.0 MPA high-pressure gas ports

- New height-sensing capability has significantly increased cutting speed in lighter gauge materials

- Pierce detection is standard, which allows for the machine to change material thicknesses without sacrificing cut quality and process time

- Secure single-action door. (An operator favourite)