EKO full-servo press brakes are manufactured to the strictest-quality standards. The Q345E steel frames are annealed to 1200° before undergoing precision machining and a careful assembly process by experienced professionals.

EKO press brakes work on the dual-servo principle with the Y1 (left ram) and Y2 (right ram) axes controlled by powerful SANYO servo motors. This design allows for the highest speed and precision available, and ensures very low running costs. EKO press brakes come equipped with rapid front-loading quick clamps that save time on tool changes and improve efficiency.

Due to their high speed and precision, they are widely used in robot-bending cells.

EKO partner with high-end robot manufacturers such as KAWASAKI, KUKA and YASKAWA to ensure their machines are perfectly suited for high-speed robot-bending applications.

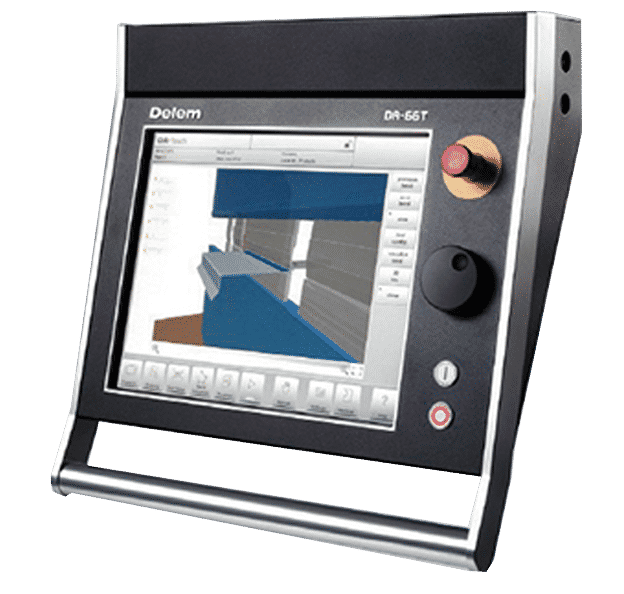

The EKO press brake machines come standard with “NC max” CNC control, similar to AMADA NC9 control. STEP (Germany) and DELEM (Netherlands) graphical controls are also available and are our preferred option for the Australian customer. The highly recommended DELEM DA66T control comes with Profile-T offline software and a large touch screen with clear graphics for easy CNC programming and fool-proof operation.

By building on Japanese and European-style servo machines, EKO have proven their superiority by dominating over 70% of the Chinese domestic market for high-speed electric-servo press brakes.

Full-servo press brakes not only have much higher production rates but are also very economical when it comes to power usage.

Accurate & Fast:

Y axis 0.01 / 100mm Y1 & Y2 Speed 1 – 25 m/min

X axis 0.02 / 600mm X Speed 1 – 30 m/min

Z axis 0.1 / 100mm Z1 & Z2 Speed 0.1 – 20 m/min

R axis 0.1 / 100mm R Speed 1 – 15 m/min