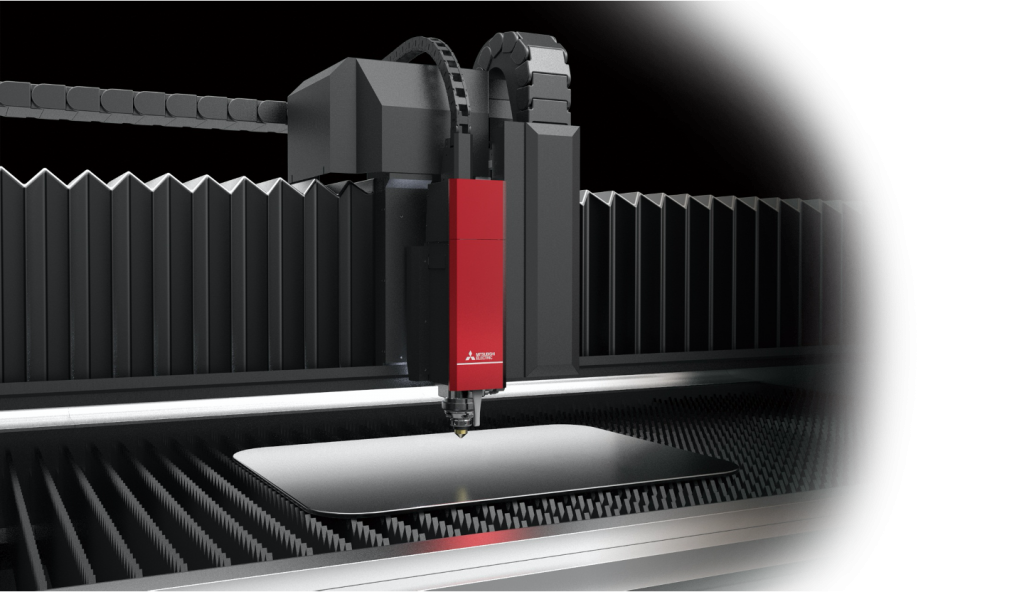

Mitsubishi’s Advance eX-F series is the premier product in our fiber line up.

Mitsubishi Electric is a world leader in industrial electronic controls and components and part of their mission is to provide the best products and services with unsurpassed quality.

The new control improves maximum processing speed by 100%, while also improving accuracy and reducing processing time on small geometries and holes. Many new control features include a customisable home page, expanded cutting-condition library, and robust maintenance screens. For improved operation, the machine now has an automatic safety door and two high-pressure-assist gas ports. The Advance eX-F series comes standard with Mitsubishi’s all-in-one Zoom head. The Zoom head utilises beam mode manipulation to process a full range of materials automatically without any setup. The Zoom Cutting Head’s all-in-one design includes an Auto-Focus Focal Range from 3.75 to 10 inches, HPP Pierce Technology, and is backed by the industry’s best magnetic breakaway fiber head.

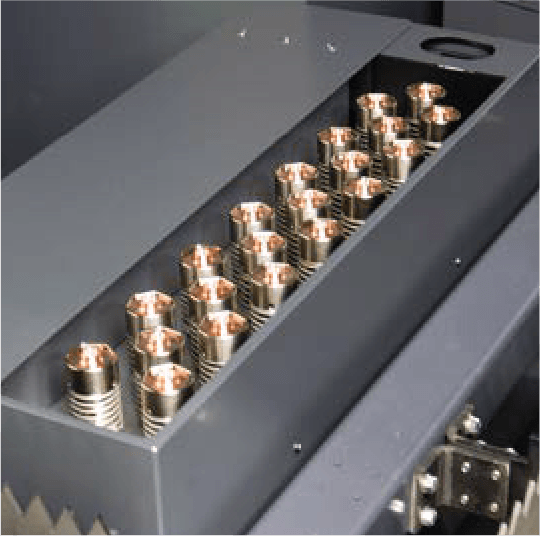

The system ensures unmatched efficiency by eliminating the need for lens cleaning or cartridge changing. Its reduced nozzle centring time ensures productivity and a wealth of benefits that come with the fastest cutting-machine, per kilowatt, in the industry.

OVERVIEW

- Adjustable M800 19” smooth operation control

- Improved productivity with a new control device

- One-button-press automatic safety door

- Two high-pressure-assist gas ports

- All-in-one head design

- HPP Pierce technology

- Autofocus focal range from 3.75 – 10 inches

- No lens cleaning required

- No cartridge changes

- Reduced nozzle centring

- The industry’s best magnetic breakaway fiber head

- Manipulate the beam mode to cut thin and thick material automatically